From development

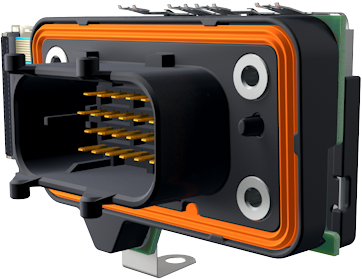

to complex assemblies

MEKU creates value for you along the entire value chain. A productive synergy between our competency centres for metals, electronics and plastics generates the following advantages for you, the customer: a plus in know-how, a plus in production technology and a plus in innovative power. As a system supplier we develop and produce complex, sophisticated assemblies at the highest level of quality.

- Conception, consultation and planning

- Development and design

- Project management

- Prototyping

- Toolmaking and mould construction

- Plant and machinery construction

- Series production

- Supply chain

- Expertise in all the relevant production processes