Clever Mold System ensures the greatest possible flexibility at the Competency Centre Plastics

20. April 2018 | in News

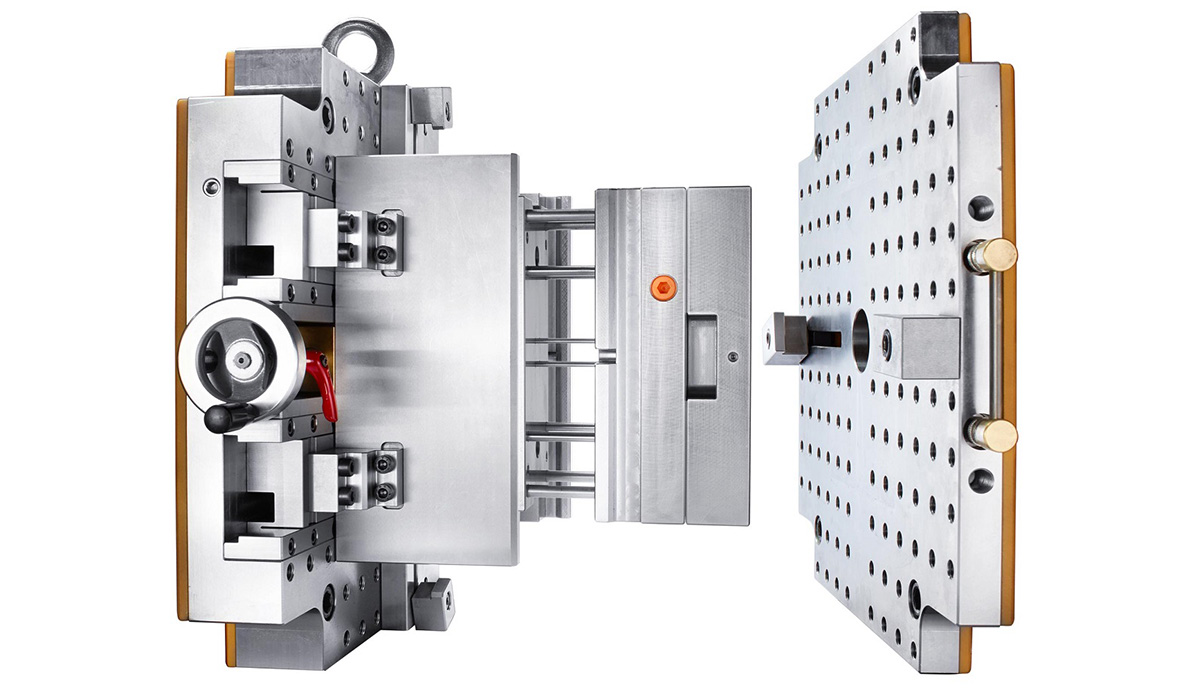

The Competence Center Plastics is breaking new ground in the production of very small series and prototypes. In order to be able to work more efficiently and cost-effectively, the plastics specialists at MEKU tested Hasco’s A8500 Clever Mold System over a longer period of time.

“We were looking for a solution to significantly reduce our set-up times on our injection molding machines and increase our flexibility,” explains Matthias Jäger in an interview with the industry magazine “werkzeug & formenbau”. In the recently published article, the authorized representative and Head of Sales & Development reports on the experiences that have been made while testing the Clever-Mold System and why MEKU Kunststoff has decided in it’s favor as a permanent solution. “Tools and production can now be far better aligned to a holistically optimized production,” Jäger summarizes the benefits of the clever system, which is based on its own tool philosophy, that has really convinced the specialists at MEKU. By using the Clever Mold System, production and tool production can now not only be created from the perspective of just one assembly: “We are now in a position to take better account of the whole situation on the machine.” In addition, the Hasco system allows the plastics experts to redefine the handling of the number of pieces: this can be made significantly more cost-effective, as the system makes a growing tool solution as well as a short reaction to changing market conditions possible.

By using the Clever Mold System, the MEKU Competency Centre Plastics offers mass production quality right from the start – fast, flexible, cost-effective and uncompromising. This radical change goes beyond production itself: “It also applies to design and planning,” explains Matthias Jäger, why a lot has changed at MEKU since the test phase of the A8500. Jäger is certain: “By using this system we are very well equipped for the future. ”

Please read the whole article (German language) from “werkzeug & formbau” here: https://www.werkzeug-formenbau.de/spritzen-giessen/meku-setzt-auf-a8500-clever-mold-system-von-hasco-126.html